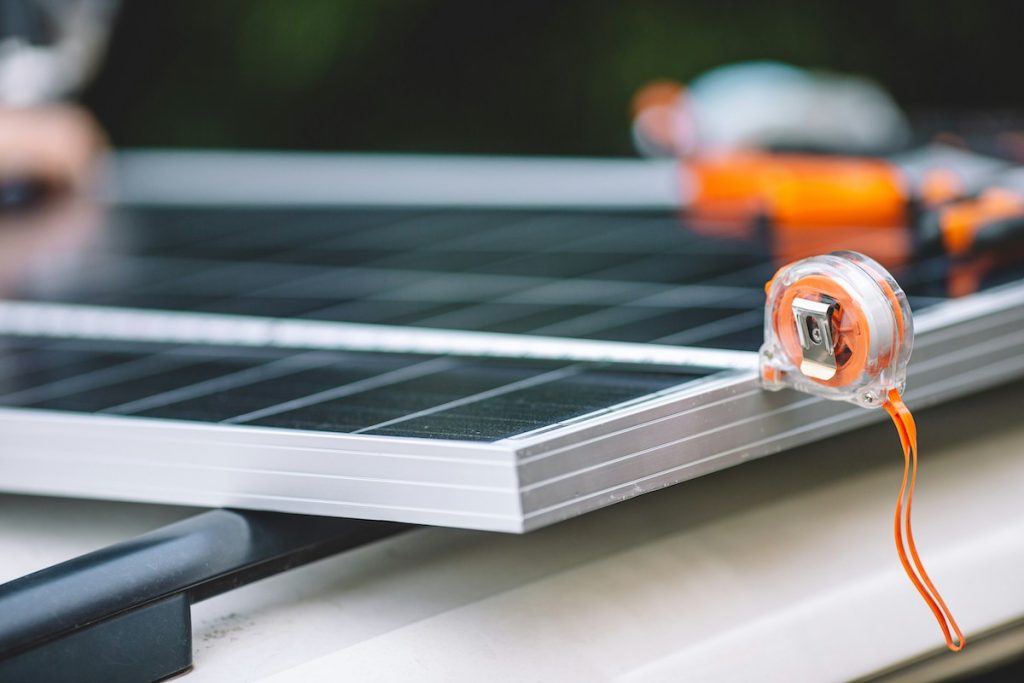

Solar panels are primarily made of silicon cells, aluminum, and glass. Here's what happens when it's time to recycle these parts.

Choosing to go solar is one of the best ways to gain energy independence, all while bettering the environment. Solar panels last upwards of 25 years and save you thousands of dollars in the long-run. But what happens when they do eventually wear out? Unfortunately, many solar panels–despite being made of recyclable and reusable materials–end up in landfills.

In this blog post, we explore how solar panels are constructed and later disassembled for recycling. We’ll also share some of the newer initiatives in place to increase the percentage of recycled panels.

What materials are solar panels made of?

In general, there are three main parts of a solar panel or module: silicon cells, aluminum, and glass. Other materials, such as a backsheet made from plastic, ethylene vinyl acetate (EVA) glue, and a standard 12V wire may also be used.

Silicon Cells

Two types of solar technology are used for generating electricity: photovoltaic (PV) panels or modules, and concentrating solar power (CSP). The main difference between the two is that PV panels use the sun’s light to make electricity and CSP uses the sun’s heat.

PV panels and modules account for the vast majority of US solar panels and the most common type of PV panel is made using crystalline-silicon (C-SI).

Breaking this down a bit further, crystalline silicon comes in two forms. Monocrystalline solar cells are cut from one large, pure crystal while polycrystalline solar cells require multiple crystals to be melted together. Solar cells made using monocrystalline tend to be more efficient than polycrystalline solar cells and they also cost more.

Aluminum

Aluminum is used for the metal frame of the solar panel and for busbar wiring. Metal frames are important because they keep everything in place and also protect the panel against the elements–inclement weather, for example. They are also used to mount the panels to the roof.

Busbar ribbon is what fills the space between the solar cells and it allows electricity to flow through the panel. As a rule of thumb, the more busbar ribbon there is, the greater the efficiency of the panel.

Glass

Glass makes up the top layer of a solar panel. It’s a clear, thin layer that measures about 6-7 millimeters thick. Glass is effective in protecting the solar cells from falling objects and helps regulate both heat and humidity within the panel.

Even though the layer of glass is super thin, it actually accounts for about 97% of the weight of the panel. Although heavy, glass is well-suited for solar panels because it is durable, affordable to make, and easy to recycle.

How long do solar panels last?

Solar panels are built for long-term use, and similar to suitcase testing, panels go through rigorous rounds of testing to make sure that they’re as durable as designed. They’re not only strong and built to last, but they emit 25 times less carbon dioxide compared to coal-powered electricity.

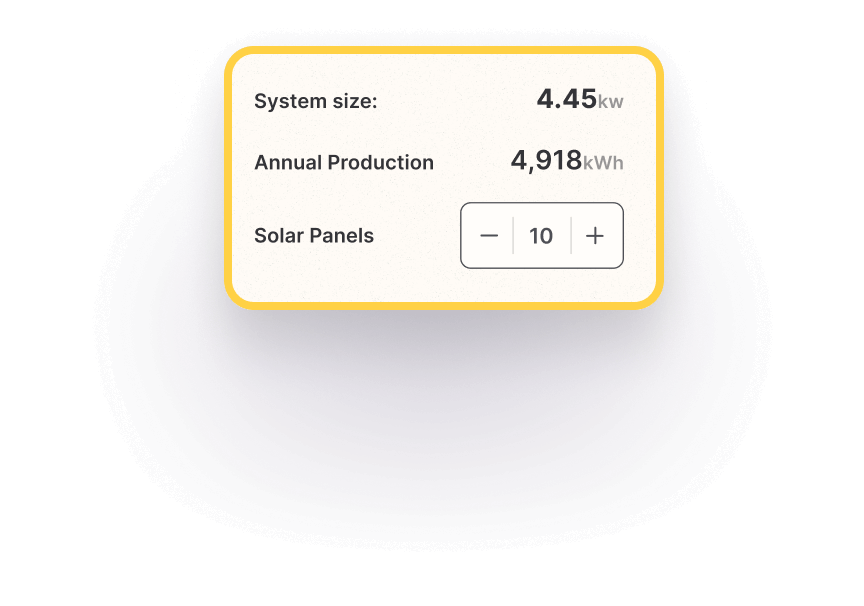

In general, solar panels should last about 25 years. The rate of degradation is an important factor to consider when estimating the lifespan of your solar system. According to a study from National Renewable Energy Laboratory (NREL), the average degradation rate is 0.50% across all solar panels. That means you could still expect your solar output to be about 89% of its original output after 25 years.

At Monalee, we use LONGi 400w solar panels for our installations. LONGi panels feature advanced cell technology, high performing modules, and are able to withstand high snow and wind conditions. Monalee homeowners also benefit from LONGi’s 25-year warranty for materials and processing and a 30-year warranty for extra linear power output.

What happens when solar panels no longer work?

In theory, solar panels are–for the most part–recyclable. However, the process of separating materials can be tedious and require special machinery.

On top of it being difficult to extract the valuable materials from the solar panels, it can be costly. As reported here, recycling solar panels costs between $20 to $30 per panel while the materials recovered are worth between $3 to $12. This leaves a net cost of $8 to $27, which is up to 13 times the cost of landfilling.

During the disassembly process, the aluminum frame should be removed and the glass is usually separated along a conveyor belt. Almost 95% of the glass is reusable and the metal frame is 100% reusable. In fact, metal parts from the panel are often used to re-mold cell frames.

The materials remaining are then treated in a thermal processing unit at super high temperatures so that the encapsulating plastic evaporates. Being under extreme heat also makes it easier for the cells to be separated.

New innovations in solar panel recycling

As more and more homeowners switch to solar, more PV panels and modules will need to be recycled. According to an article in The Union of Cornered Scientists, only about 10% of solar panels in the United States are currently recycled.

While this is definitely a discouraging number, significant progress is in the works. Washington State now requires PV module manufacturers to either take back their panels or reuse or recycle the modules at no cost to the homeowner. Companies like First Solar can recover about 90% of their solar panel materials while Solarcycle aims to recycle 95% of their solar panels.

Final Thoughts

Making the switch to solar energy is one of the best things you can do for your financial future and for the future of the planet. Solar panels are designed to be durable and should last you up to 25 years (sometimes even longer). While solar panels are made from materials that are highly recyclable, only about 10% of panels are actively being recycled. That said, new initiatives are rolling out that ensure that this number increases.